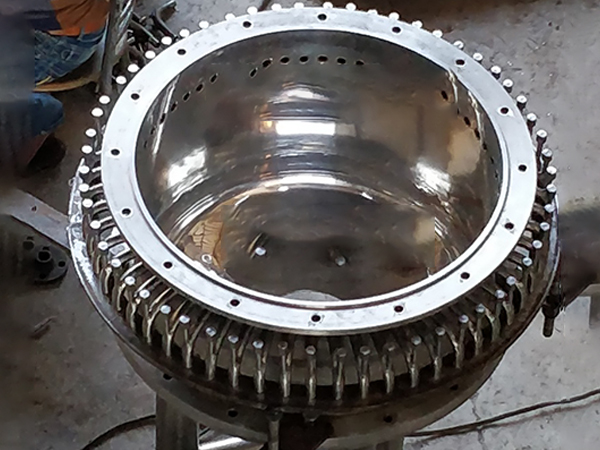

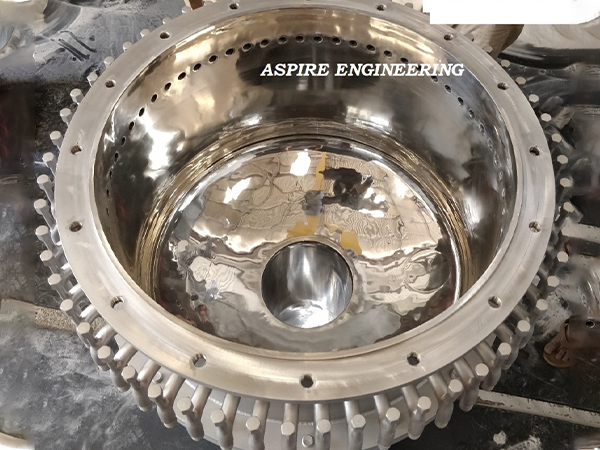

Distribution Header

Distribution Header improves CD basis weight profiles, deflocculates stock, and ultimately sheet formation in a variety of head boxes, hydraulic formers, and vats.

With the water dilution system, sheet profiles can be optimised, saving money and giving the papermaker an edge. With its modular construction, it can be installed in a machine area or basement, increasing head box performance.

With the Octopus Header, you can remove excess air from stock. A diffuser plate and air pad dampen vibrations and remove pulses before they affect sheet formation. An air bleed valve removes excess air from the Octopus' top.

Advantages of the System -

- Improves the basis weight profile

- User-friendly

- Low cost

- Easy to clean

- Wide range of stock flows

- Compact and easy to install

- Retrofittable into existing machines

- No balance or re-circulation needed

- A low-maintenance design

- Operates with existing stock preparation in most cases

- It can be used with a manual or automatic water dilution system

- Improves formation by deflocculating stock

- When used with a diffuser plate, it acts as an attenuator, removing pulsation