Applications -

- Effective separation and recovery of fiber, fines, and fillers from white water from paper machines.

- Thickening low to medium freeness pulp, particularly in applications requiring good discharge consistency.

Key Features & Benefits of Aspire Disc FIlter -

The economic and environmental benefits of recycling water, fiber, and filler are that they reduce the amount of clear water used, the load on effluent treatment plants, and chemical usage.

- Reliable operation

- Superior filtrate quality

- Simple to clean filter media and sections

- Flexible installation

- Lower energy costs

- Recovery and reuse of fibers in white water

- Reduced water consumption and effluent expenses

Working Principle of Vacuum Disc Filter -

When the slurry enters the filter through the inlet chamber, it is equally distributed down the length of the vat. The pulp mat starts to form under the influence of gravity, ensuring optimal dewatering qualities. The filtrate is discharged into the corresponding filtrate channels in the central shaft through the open-grid type sectors. The spinning shaft is connected to the filtrate valve, which opens and shuts the channels to the vacuum created by the barometric legs. As the filtrate enters the valve, it can be switched between clear, cloudy and super-clear filtrate if necessary. Once the sectors have emerged from the suspension and have been drained, the pulp mat is dewatered under vacuum. The pulp mat is separated using a water iet employing the knock Off Shower nozzles above sectors, and it is then discharged through chutes inside the vat and sent in to a screw conveyor .An oscillating nozzle cleans the mesh of filter before commencing the filtering procedure.

Advantages of Aspire Disc Filter -

- CENTER SHAFT : Aspire Disc Filter has stable & sturdy center shaft that enables the disc filter to function smoothly

- EXCELLENT FILTRATION : It is easier to maintain clean filtrate when the filter is internal volumes are smaller. Disc Filter has small internal volumes in the shaft, filtrate valve, and sectors to offer the highest quality filtrate possible. The clear filtrate can be divided into clear and super clear filtrates, depending on the process requirements.

- SECTORS & FILTERING MEDIA : Each disc is composed of twenty open-grid type sectors that are connected to corresponding filtrate channels in the shaft. The design of the open-grid sector reduces the likelihood of pulp and debris accumulating inside it by providing over 90% open space. This design allows for a spray water iet to pass through the open sector and clean the filter media from both the inside and outside which enhances its effectiveness.

- FLEXIBLE INSTALLATION : The clockwise and counterclockwise rotations of the Disc Filter are both supported by its design. This gives planners more options when laying out the mill, for instance, if a series or parallel operation mode is required.

We Also Provide Below Mentioned Spares Parts And Services For All Types Of Disc Filter

- Segment / Cassette Holder

- Segment / Cassette

- Polypropylene Shrink Fit Filter Bag

- Knock Of Shower Nozzle

- Oscillating Shower Nozzle

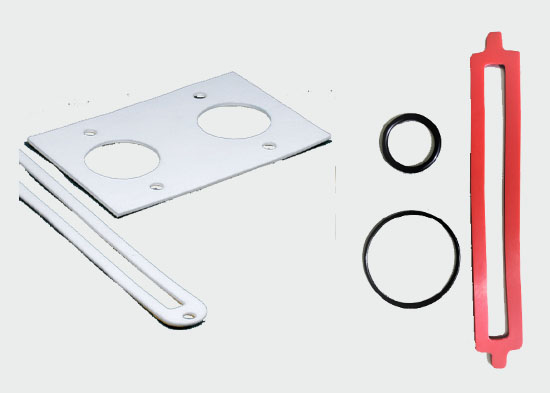

- Polypropylene, Rubber & Silicon Gasket

- Rubber & Silicon “O” Ring

- Wear Plate / Wear Disc

- Bush Bearing

- Conveyor Screw

- Technical Assessment of Second Hand & Old Disc Filter

- Modifications to Improve Performance of Existing Disc Filter

- Installation & Commissioning of Second Hand Disc Filter

Spares of Aspire Disc Filter -

Cassette

Cassette Holder

Wear Plate

PP Bags for Segment / Sector

Filtrate Valves

Gaskets